About GRIPPER FOR RAPIER WEAVING LOOMS

ALL RAPIER LOOMS GRIPPER AVAILABLE

PICANOL - GTM, GTX, GAMMA2002, GAMMAX, OPTIMAX,

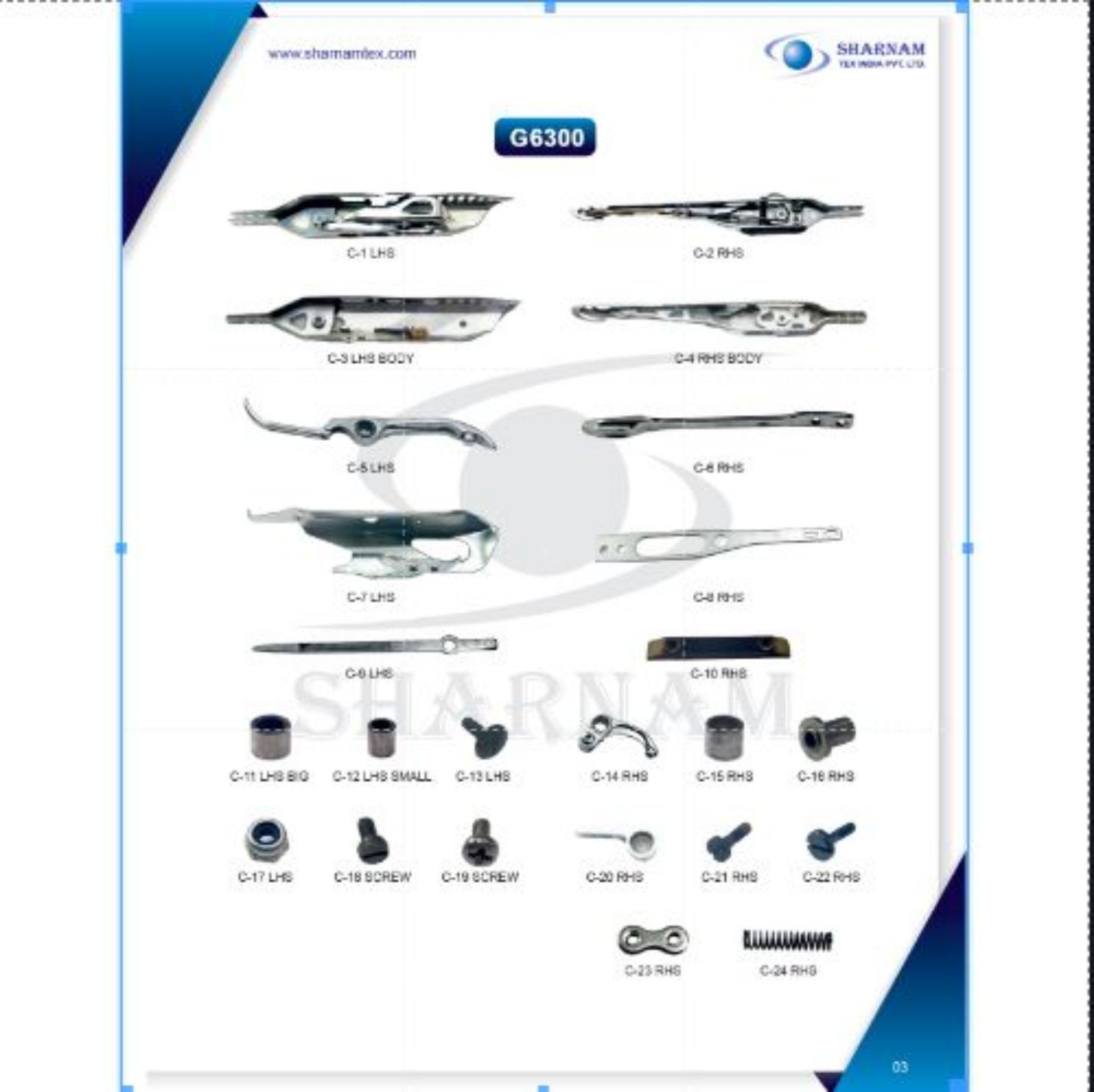

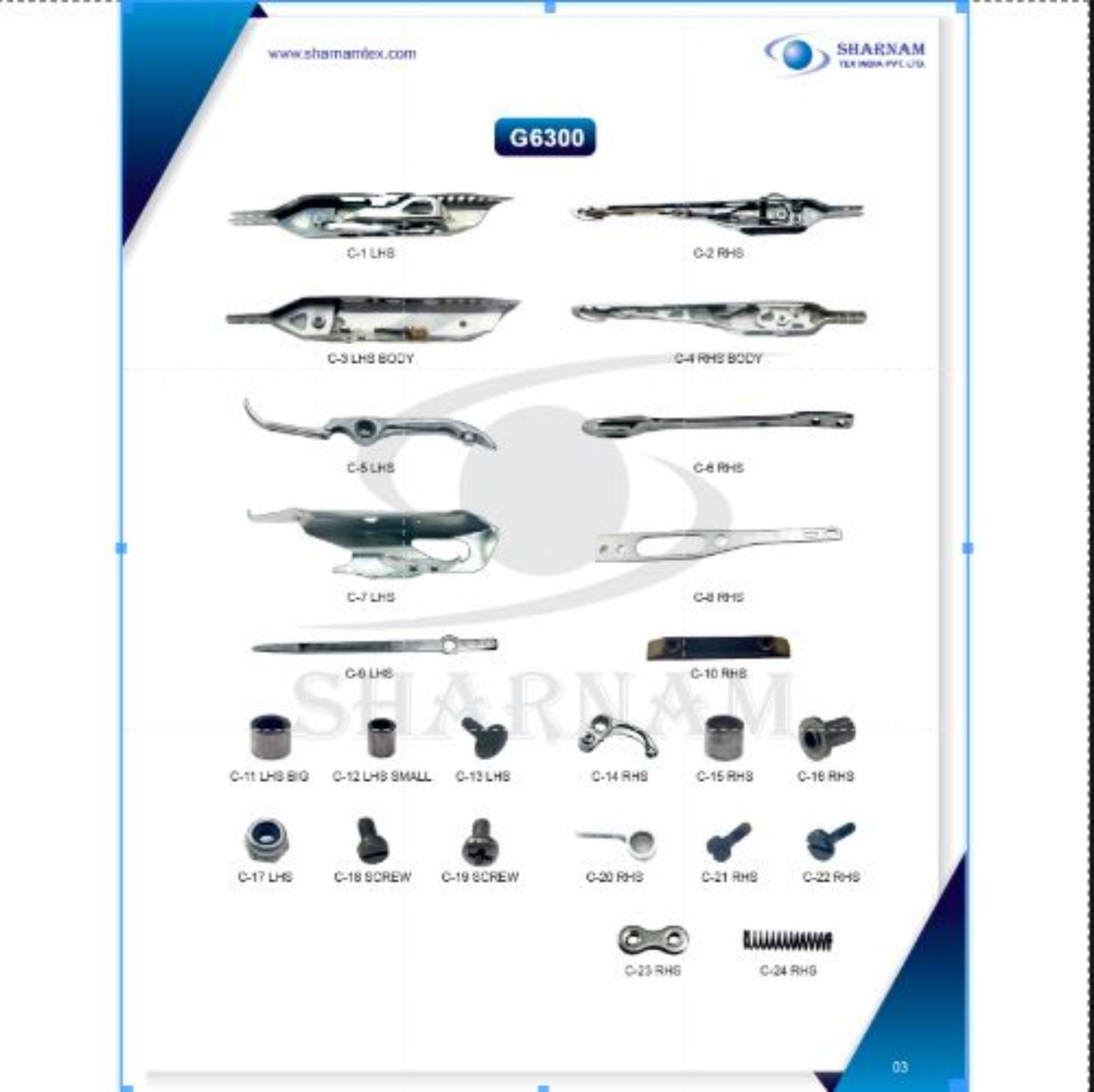

SMIT - TP600, GS900, G6300, NPFAST

DORNIER - HTV, HTVS, GTN, GTNS8

SOMET - THEMA11E, SM92/93, SUPER EXCEL

ALL COMPLETE GRIPPER & ACCESSORIES ARE READY IN AVAILABLE

Precision Engineering for High-Speed WeavingOur grippers for rapier looms are manufactured to withstand continuous industrial use at speeds ranging from 250 to 450 RPM. Designed with high-grade materials and customizable surface finishes, these components ensure reliable, precise performance during extensive weaving operations, optimizing textile production quality and output consistency.

Adaptable Design for Custom RequirementsRecognizing the varied needs of the textile industry, we offer grippers with adaptable surface finishes. Whether you require a standard or specialized grip, our customization options ensure optimal compatibility with different weaving machines and fabric types, facilitating seamless integration into your existing processes.

FAQs of GRIPPER FOR RAPIER WEAVING LOOMS:

Q: How does the gripper for a rapier weaving loom function during the weaving process?

A: The gripper in a rapier weaving loom is responsible for holding and transporting the weft yarn through the looms shed. It securely clamps the yarn and carries it from one side of the loom to the other, enabling efficient and accurate weft insertion at speeds of 250 to 450 RPM.

Q: What are the benefits of using a customized surface finish on the gripper?

A: A customized surface finish improves grip, reduces friction, and minimizes wear on both the gripper and the yarn. This customization ensures compatibility with various yarn types and helps maintain consistent weaving quality over extended periods.

Q: When should a gripper for a rapier weaving machine be replaced?

A: The gripper should be replaced when you notice signs of excessive wear, reduced grip, or inconsistent weft insertion. Regular inspection helps identify these issues early, preventing damage to the weaving machine and ensuring uninterrupted production.

Q: Where are your grippers for rapier weaving looms supplied from?

A: We are based in India and act as exporters, suppliers, and traders, providing high-quality grippers to textile industries both domestically and internationally.

Q: What is the installation process for the gripper component?

A: Installation involves carefully mounting the gripper onto the dedicated carriage within the rapier loom according to the machines specifications. Professional guidance is recommended to ensure proper alignment, maximum efficiency, and safety during operation.

Q: How is the gripper used in industrial textile applications?

A: The gripper is a vital component in industrial weaving machines, specifically configured to facilitate rapid weft insertion during continuous textile production. It supports a wide range of fabrics and increases the efficiency of weaving processes in large-scale operations.

Q: What advantages do your grippers offer for weaving machine operations?

A: Our grippers are engineered for durability and high-speed operation, ensuring minimal downtime and superior weaving accuracy. Customizable finishes further adapt the component to different production needs, elevating overall textile quality and productivity.